Table of Contents

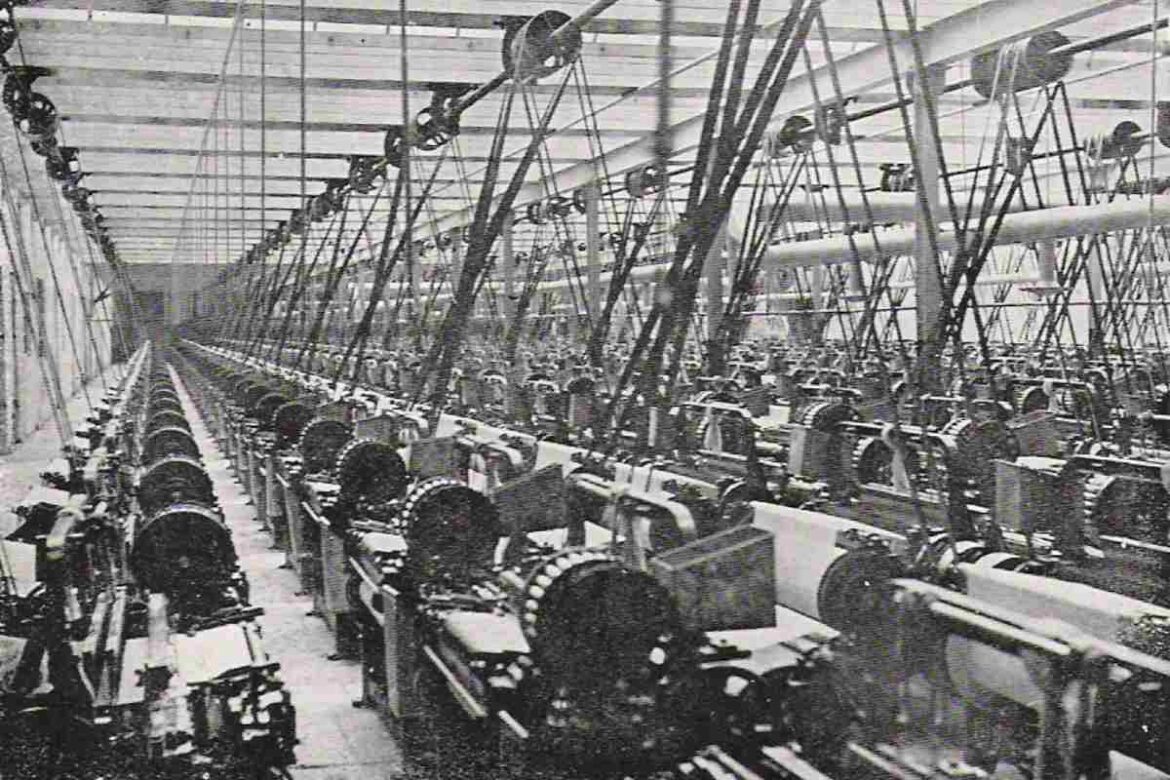

Legacy Does Not Mean Obsolete

A “legacy” asset is simply one whose original vendor support or technology generation has been superseded; it is not, by definition, unfit for purpose. Many plants continue to rely on machinery installed two or even three decades ago because it still meets throughput and quality targets with far less capital outlay than an all‑new line. Analysts list reliability, fear of disruptive change, limited funds and the absence of a clear return on investment as the top reasons executives stick with proven systems .

Case in Point: The MDD112D Servo Motor

Bosch Rexroth introduced the MDD112D series in the 1990s for packaging, printing and material‑handling axes that demanded fast acceleration at moderate torque. The MDD112D‑N‑030‑N2M‑130GA0 variant delivers 38 Nm continuous torque at standstill and 3 000 rpm nominal speed, backed by a digital multiturn encoder for closed‑loop positioning. Even today that performance is plenty for a form‑fill‑seal machine or pick‑and‑place robot cycling under one second — demonstrating how a well‑sized legacy motor can remain competitive long after its debut.

Seven Strategic Reasons to Stay the Course

| Reason | How It Plays Out on the Factory Floor | MDD112D Example |

| It still works — and works well | “Good enough” output avoids the risk of early‑life failures common to brand‑new platforms. | Thousands of hours between bearing overhauls keep OEE high. |

| Service continuity outweighs innovation | 24/7 lines can’t spare the weeks of commissioning an upgrade demands. | A drop‑in spare from surplus stock gets a palletizer running in minutes. |

| Complex integration hurdles | New drives may require PLC rewrites, field‑bus upgrades and mechanical adapters. | Existing drives talk SERCOS; swapping them all for EtherCAT would touch every cabinet. |

| Capital constraints | Budget cycles may favor incremental improvements over multi‑million‑dollar retrofits. | Rewinding a stator costs <15 % of a new motor. |

| Trained workforce & tribal knowledge | Operators know every quirk of the legacy line; retraining slows production. | Maintenance techs can diagnose an MDD fault by ear. |

| Regulatory validation already done | In pharma or food, re‑qualifying equipment can take months. | The MDD‑driven blister packer has validated cleaning protocols in place. |

| Sustainability by extension | Extending asset life reduces embodied carbon versus scrap‑and‑replace. | Refurbishing the motor keeps 90 kg of steel and copper in service. |

Modernising Without Replacing

Sticking with legacy equipment does not preclude incremental advances:

- Sensor retrofits — Add vibration or temperature nodes to the MDD’s endbell and stream data to a condition‑monitoring dashboard; no changes to the motor windings or drives are required.

- Drive‑level upgrades — Pair the MDD with a newer IndraDrive or third‑party inverter that speaks both SERCOS and Ethernet/IP, bridging old mechanics to modern controls.

- Spare‑parts strategies — Aftermarket specialists remanufacture original windings, encoders and seals for long‑term parts availability.

When an Upgrade Becomes Inevitable

Despite their virtues, legacy assets have limits: component obsolescence, lower energy efficiency and the absence of native cybersecurity features. Plants should assemble objective triggers — for example, a 20 % year‑over‑year rise in unplanned downtime or the unavailability of critical spare parts — to signal when replacement finally beats repair. Until those thresholds are crossed, a well‑maintained motor such as the MDD112D‑N‑030‑N2M‑130GA0 can remain a productive, profitable cornerstone of the line.

Bottom Line

Choosing to keep legacy equipment is not the result of inertia alone; it is often a rational balancing of risk, cost, and continuity. The enduring relevance of the MDD112D servo motor shows that “old” can still be efficient, accurate and sustainable — provided factories couple careful maintenance with selective modernisation. In many cases, the smartest path forward is not to abandon yesterday’s hardware, but to help it talk to tomorrow’s factory.